Streamlining Manufacturing

Streamlining Manufacturing: USE CASE #1

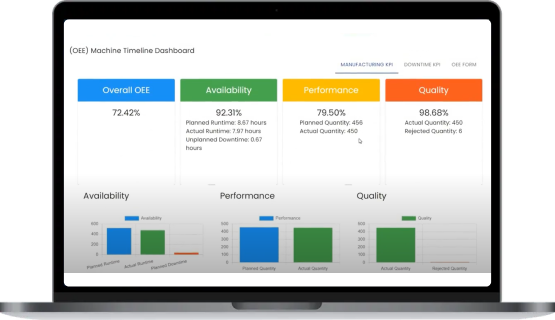

Boosting OEE

Metrics in Pharmaceutical Manufacturing

Through ARIZON Systems' solution, the plant gains the ability to analyze OEE data in real-time, providing insights into equipment performance and production efficiency.Leveraging the insights from real-time OEE data analysis, the plant initiates continuous improvement efforts aimed at optimizing production processes and minimizing downtime.

Resulting in a 15% Increase in OEE Metrics:As a direct outcome of these improvement initiatives, the plant achieves a notable 15% increase in Overall Equipment Effectiveness (OEE) metrics.

Streamlining Manufacturing: USE CASE #2

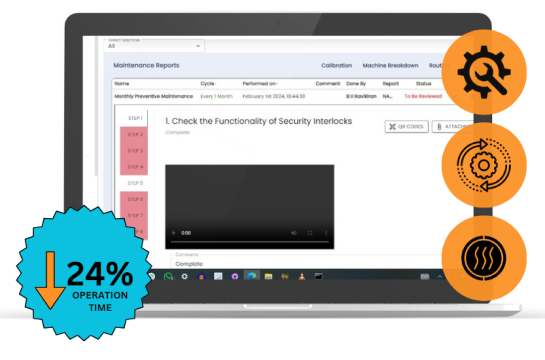

Revolutionizing

Maintenance, Cleaning and Changeover Efficiency

The pharmaceutical production line adopts ARIZON Systems' AR SMART platform to streamline fool proof operational processes.

Through AR Smart, maintenance, cleaning and changeover procedures are meticulously digitized, SOP wise step interlocking systems enabling precise, traceable and efficient execution.

As a direct result of these advancements, operational time is reduced by an impressive 24%, facilitating rapid transitions between production runs and batch changeovers.

Streamlining Manufacturing: USE CASE #3

Empowering Live Tracking

for Enhanced Efficiency

With the Live Tracking Module in place, the facility gains the capability to continuously monitor live parameters that defines the process output.

Through the Live Tracking Module, production data is updated instantaneously, providing stakeholders with timely insights and actionable information.

Leveraging real-time data provided by the Live Tracking Module, the facility experiences a 10% improvement in response time to production issues and deviations.

Lab Advancements

Lab Advancements:

USE CASE #1

Seamless Procedure

Management

ARIZON Systems' SMART LAB offers an intuitive platform for creating, scheduling, and executing laboratory protocols.

The system provides seamless integration with existing SOPs, ensuring consistency and compliance with regulatory standards. With the LES in place, researchers and lab technicians experience a significant reduction in procedure execution time, estimated at 30%.

Lab Advancements:

USE CASE #2

Ensuring Regulatory

Adherence

Integration of ARIZON Systems' SMART LAB to ensure compliance with stringent industry regulations such as Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP).

SMART LAB automates compliance tasks, ensuring adherence to regulatory standards and guidelines.

The system generates comprehensive, audit-ready reports, facilitating seamless regulatory inspections and documentation.

Adoption of ARIZON's LES reduces audit preparation time by 35%, streamlining regulatory inspections and compliance processes.